Why 'rebuilds' are not breaking the bank or the planet.

30/01/25, 14:15

There are many reasons to consider the purchase of a used machine over a new one.

The primary one is of course cost. Rebuilding is a cost effective option for quality used machines. With new European machinery often being priced out of reach, a reliable, good quality used model is worth considering.

It may often make sense, for instance if the user is looking to duplicate an existing machine with the same type. This provides commonality for spare parts and established operator knowledge.

The best option for the used route is a rebuilt machine.

Rebuilding delivers the base of a quality, established machine, coupled with the latest electrics and electronics, along with guarding and safety conformity.

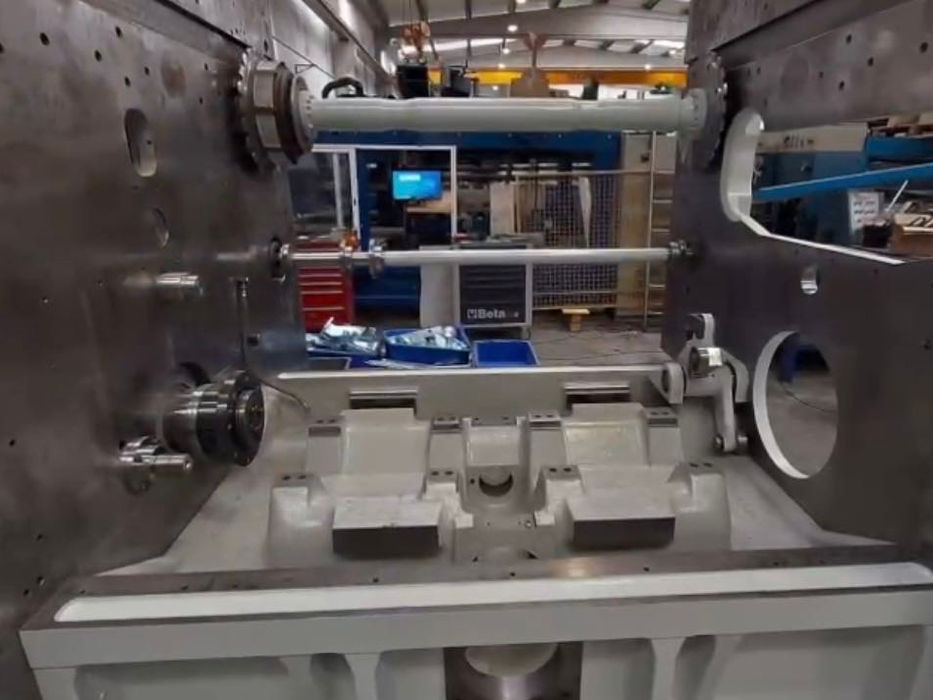

The adage of reconditioning being “a lick of paint and a dob of grease”, could not be further from the truth. At ID, we thoroughly audit the machine, in most cases, stripping to the side frames and then begin re-assembly, replaces worn and broken parts with the latest technology and in many cases, actually improving on the original.

With our facility in Portugal, we can offer the above with a consistently reliable and successful outcome. This gives us the confidence to provide a machine with full warranty and back up service at a fraction of the new price.

See below for a start to finish graphical illustration on both a recent Bobst 1600 and Gopfert Casemaker rebuild that were both undertaken at our specialist workshop in Portugal.